ABS Plastic Sheets – Impact Resistant and Thermoformable for Industrial, Automotive & Commercial Applications

TA FU CHI PLASTIC offers a comprehensive range of high-quality ABS plastic sheets designed to meet the demands of various industries. Known for their excellent impact resistance, thermoformability, and diverse surface textures, our ABS sheets are used across automotive, furniture, signage, and manufacturing sectors.

These thermoplastic sheets combine strength, flexibility, and visual appeal, and are easily processed through vacuum forming, CNC machining, and heat bending. Whether you're designing vehicle interiors, building commercial fixtures, or prototyping custom parts, our ABS sheets deliver consistent quality and performance. We also provide full OEM/ODM support, including custom sizes, textures, and colors to match your unique project needs.

________________________________________

Available ABS Sheet Types:

Our ABS sheet lineup includes multiple finishes and performance options. Explore each sub-category for detailed specifications.

• Wood Grain ABS Sheet -Combines the natural appearance of wood with the strength of ABS. Perfect for furniture, cabinetry, and decorative interior applications.

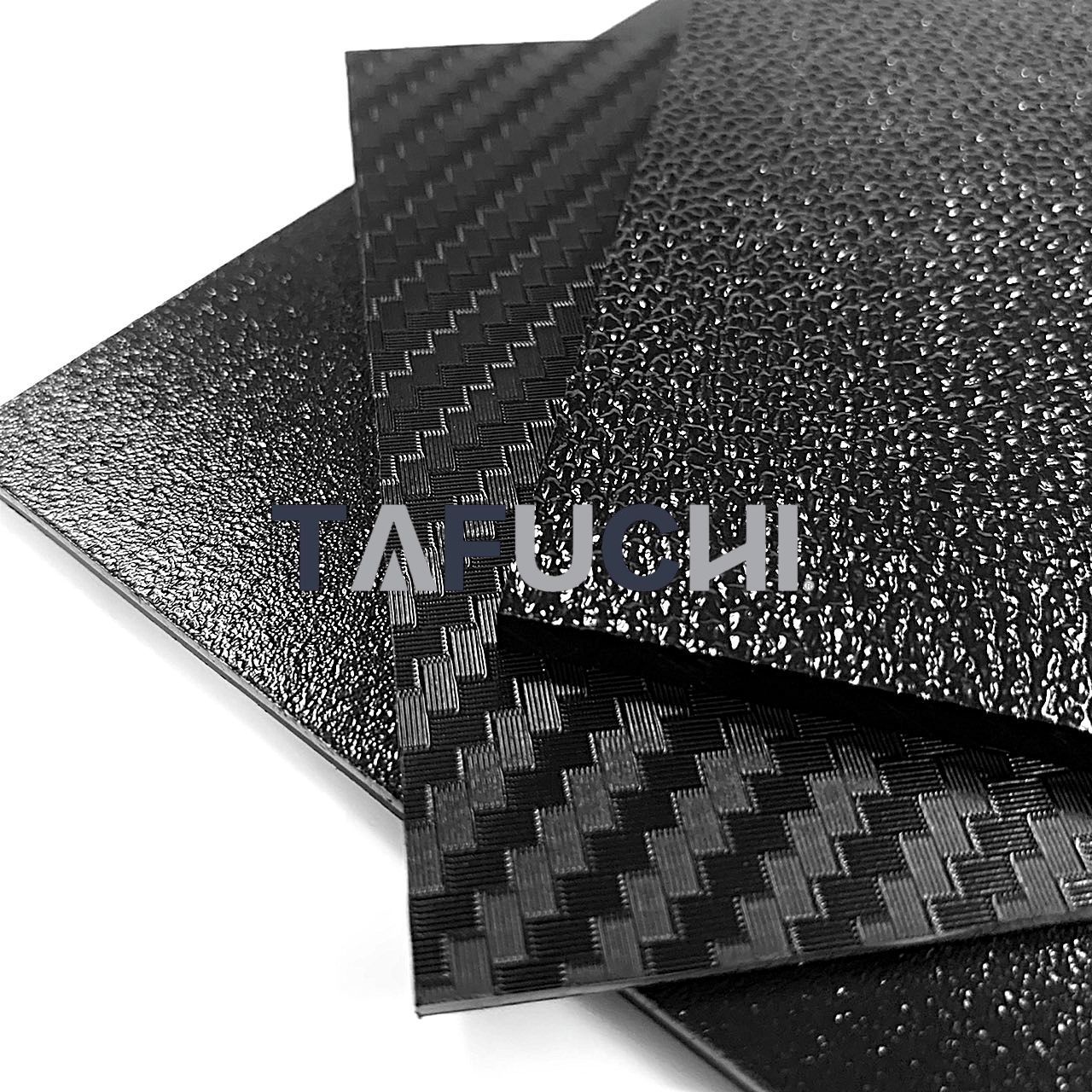

• Textured ABS Sheet -Features a matte, anti-slip surface ideal for industrial use, cabinet doors, and automotive interiors.

• Flat ABS Sheet -A smooth-surfaced, multipurpose sheet suitable for digital printing, display boards, signage, and general fabrication.

________________________________________

Why Choose Our ABS Sheets?

• High impact resistance and durability

• Easy to thermoform, cut, and bond

• Wide range of finishes: glossy, matte, textured, wood grain

• Available in custom sizes, colors, and thicknesses

• Highly Versatile – Adaptable for a wide range of applications and designs

________________________________________

Common Applications of ABS Sheets:

• Automotive interior panels and trim

• Kitchen cabinets, wardrobe panels, and office furniture

• Retail display fixtures and advertising signage

• Equipment enclosures and industrial covers

• Suitcases, toolboxes, and protective casings

________________________________________

Whether you are developing vehicle parts, designing retail fixtures, or creating modern interiors, our ABS sheet solutions are built to perform.

👉 Browse our ABS sheet sub-categories below or contact our team for samples and customized solutions.

Professional, custom solutions

We provide high-quality, customized plastic sheets to meet industry needs, ensuring top standards. Choose us for the perfect materials for your applications.

Custom solutions

Our expert team provides guidance with various thicknesses, sizes, and colors, ensuring quality and timely delivery.

Cross-industry use

Ta Fu Chi Plastic products in furniture, automotive, bathroom, and electronics offer functionality and aesthetics.

Innovating for lead

We develop new materials, improve production, focus on custom solutions, and stay competitive.

ABS Plastic Sheets – Impact Resistant and Thermoformable for Industrial, Automotive & Commercial Applications | Durable, High-Quality Plastic Sheet Solutions for Every Application

Ta Fu Chi Plastic Co., Ltd. is a leading ABS Plastic Sheets – Impact Resistant and Thermoformable for Industrial, Automotive & Commercial Applications manufacturer in Taiwan with over 30 years of expertise in plastic extrusion. We specialize in producing high-performance materials such as acrylic sheet, matte acrylic sheet, acrylic edge banding, and pvc wood-grain sheet, all designed to meet the evolving demands of the furniture and interior design industries. By combining advanced manufacturing processes with flexible customization options, we offer solutions that are not only visually striking but also durable, cost-effective, and easy to process. Our commitment to quality and precision has made us a trusted partner for global B2B clients across kitchen, wardrobe, and bathroom furniture manufacturing.

Headquartered in Tainan, Taiwan, Ta Fu Chi Plastic serves customers worldwide with a focus on innovation, reliability, and environmental responsibility. We continually develop materials that meet both aesthetic and functional needs—offering moisture-resistant edge banding, scratch-resistant surfaces, and rich color options. Our plastic sheets are ideal alternatives to traditional materials like glass, metal, or wood, helping manufacturers achieve modern designs with improved production efficiency. With a foundation built on customer satisfaction and long-term success, we are proud to deliver plastic sheet solutions that enhance the value and performance of today’s furniture applications.