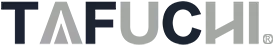

GPPS Frosted Sheets – Decorative, Light-Diffusing Panels for Lighting

GPPS diffuser sheet

Looking for a plastic sheet that diffuses light evenly while reducing glare and reflections? Our frosted GPPS (General Purpose Polystyrene) sheets are engineered for lighting covers, display panels, and privacy partitions where soft light diffusion and a clean, modern look are essential. With a matte surface that minimizes glare and resists fingerprints, these sheets are ideal for LED light diffusers, signage backings, and architectural lighting designs.

Lightweight yet rigid, GPPS frosted sheets offer excellent clarity and dimensional stability—making them a practical alternative to glass or acrylic in both residential and commercial environments. Whether you're creating ambient lighting, illuminated signage, or interior cladding, these plastic panels deliver high performance and a refined appearance.

Frequently Asked Questions

-

Q1: How does frosted GPPS differ from acrylic?

A1: Frosted GPPS offers a similar aesthetic and light-diffusing performance but is more cost-effective and easier to process. It is also lighter than acrylic, making it suitable for large-area installations. -

Q2: Can I use this sheet for outdoor applications?

A2: GPPS is best suited for indoor or sheltered environments. For long-term outdoor use, UV-stabilized materials like ASA are recommended. -

Q3: Is this sheet transparent or opaque?

A3: It is translucent. The frosted surface allows light to pass through while diffusing it, which reduces direct visibility but still offers brightness. -

Q4: Are custom sizes available?

A4: Absolutely. Ta Fu Chi Plastic offers customization in thickness, dimensions upon request.

Applications

• Display panels & signage covers for enhancing visual appeal while reducing glare in retail and commercial environments.

• Privacy screens & partitions for balancing transparency and privacy in offices, clinics, and shared spaces.

• Interior decor panels for adding a modern aesthetic to wall cladding, cabinet inserts, or furniture accents.

Features

- Soft Light Diffusion - Matte surface texture reduces glare and hotspots, creating a smooth, ambient lighting effect.

- Anti-Fingerprint & Easy to Clean - The frosted finish resists smudges and fingerprints, keeping the surface clean and attractive.

- High Light Transmission - Despite its matte finish, the sheet maintains excellent brightness and optical clarity.

- Lightweight & Rigid - Easier to handle and safer than glass, yet stiff enough for structural or mounted applications.

- Easy to Fabricate - Can be easily cut, drilled, or thermoformed for custom projects in signage, lighting, or furniture.

- Cost-Effective Alternative - Offers the clean look of acrylic at a more affordable price point.

Specification

| Thickness | Length | Width | Color | Specification |

|---|---|---|---|---|

| 2.2mm - 7mm | 1800mm | 700mm | Blue | 1. Various Colors 2. Short lead time 3. Both sides with masking film |

| 2135mm | 1200mm | Smoke | ||

| Custom Size | Custom Size | White |

APPLICATION

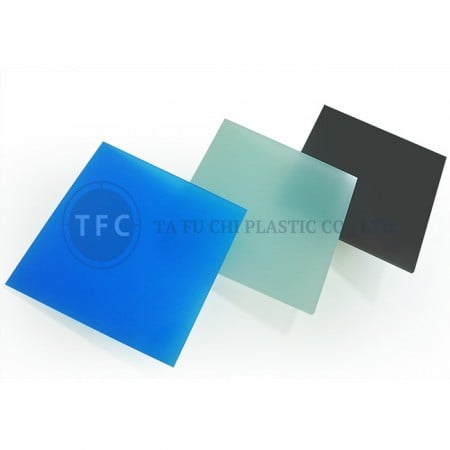

- The shower sliding door uses GPPS embossed sheet. The light can transparent through the GPPS embossed sheet.

- Use the GPPS embossed sheet as the partition between the shower place and the sink to make the place clean and enhance the privacy. The space looks simple and spacious.

- GPPS embossed sheet has the beauty of hazy effect.

- Related Products

Printable HIPS Plastic Sheets – Lightweight, Durable & Easy to Fabricate Panels

Perfect for packaging, signage, and thermoformed applications.

Deliver professional-quality prints and reliable performance at a cost-effective price. Ta Fu Chi’s High Impact Polystyrene (HIPS) Sheets are lightweight, rigid, and engineered for superior printability...

Details

Professional, custom solutions

We provide high-quality, customized plastic sheets to meet industry needs, ensuring top standards. Choose us for the perfect materials for your applications.

Custom solutions

Our expert team provides guidance with various thicknesses, sizes, and colors, ensuring quality and timely delivery.

Cross-industry use

Ta Fu Chi Plastic products in furniture, automotive, bathroom, and electronics offer functionality and aesthetics.

Innovating for lead

We develop new materials, improve production, focus on custom solutions, and stay competitive.

GPPS Frosted Sheets – Decorative, Light-Diffusing Panels for Lighting | Taiwan-Based Plastic Sheet Supplier for Global Markets

Ta Fu Chi Plastic Co., Ltd. is a leading GPPS Frosted Sheets – Decorative, Light-Diffusing Panels for Lighting manufacturer in Taiwan, specializing in the production of high-quality acrylic sheet, abs sheet, hips sheet, pmma sheet, and pvc wood-grain sheet. With over 30 years of experience in the plastic extrusion industry, we are committed to providing consistent quality, customizable specifications, and advanced sheet solutions for a wide range of industrial, commercial, and furniture applications. Our in-house extrusion technology and production control enable us to deliver plastic sheets in various finishes, colors, and thicknesses that meet international standards.

As a trusted plastic extruder and OEM supplier, Ta Fu Chi Plastic has successfully manufactured and exported over 100,000 metric tons of plastic sheets worldwide. Our diverse product range includes ps embossed sheet, acrylic capped abs sheet, and other specialty sheets designed for durability, impact resistance, and aesthetic appeal. Whether used in kitchen cabinets, bathroom fixtures, automotive interiors, or signage, our products combine function and form to meet the needs of global buyers. We continue to grow as a reliable partner in delivering tailored plastic sheet solutions that enhance manufacturing efficiency and end-user satisfaction.