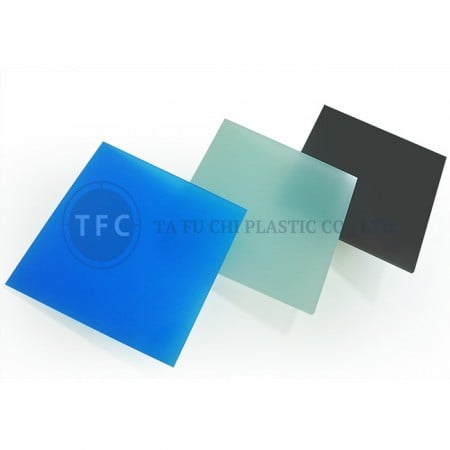

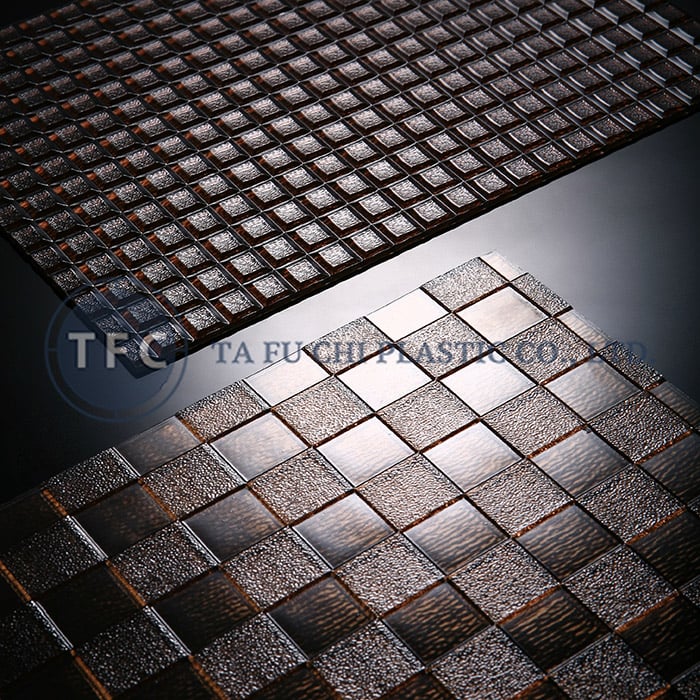

GPPS Plastic Sheets

Lightweight, Rigid & Budget-Friendly Panels for Interior Design & Decoration

TA FU CHI PLASTIC manufactures GPPS (General Purpose Polystyrene) plastic sheets engineered for optical clarity, stable rigidity, and easy fabrication performance.

Our GPPS sheets are widely used in applications where surface appearance, light diffusion, and cost efficiency are required, including shower doors, office partitions, diffuser panels, and advertising boards.

________________________________________

Why Choose GPPS Plastic Sheets?

• Excellent optical clarity for visual applications

High light transmission and clean surface appearance for transparent and light-diffusing panels.

• Stable rigidity and dimensional consistency

Maintains panel flatness and shape stability during fabrication and installation.

• Easy fabrication and processing

Suitable for cutting, drilling, bending, and light forming with consistent results.

• Balanced cost-performance for commercial use

Delivers a cost-efficient solution for decorative and light-duty manufacturing applications.

• Ideal for appearance- and light-focused applications

Designed for projects where surface aesthetics, light diffusion, and cost efficiency are key requirements.

________________________________________________________________________________

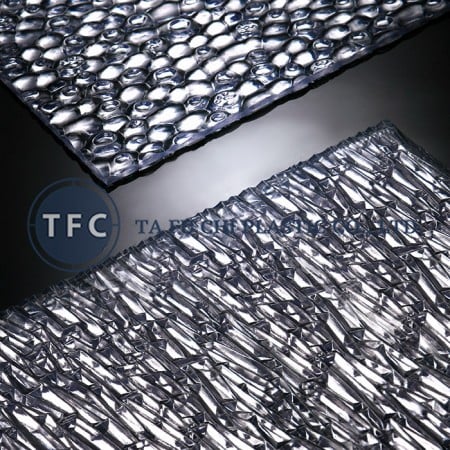

TA FU CHI offers multiple GPPS sheet surface options to match different processing and application requirements.

✅ Clear GPPS Sheets

• High optical clarity and smooth surface for transparent and light-diffusing panels

• Typical applications: Shower doors, signage, lighting diffusers, display covers

✅ Frosted GPPS Sheets

• Frosted surface reduces glare and enhances light diffusion, ideal for privacy and decorative applications

• Typical applications: Office partitions, display cases, decorative interior panels, privacy partitions

✅ Colored GPPS Sheets

• Consistent color and smooth surface for creative designs and decorative installations

• Typical applications: Signage, interior decorative panels, point-of-sale displays, custom installations

________________________________________________________________________________

Value-Added Capabilities & Customization Flexibility

• Custom thickness and sheet sizes

Produced in a range of thicknesses and dimensions to match specific project requirements.

• Surface finishing options

Clear, frosted, or colored finishes to achieve desired optical effects and aesthetic appearance.

• Precision fabrication support

Suitable for cutting, bending, drilling, and light forming, ensuring consistent results for custom installations.

• Enhanced optical and aesthetic performance

Custom options improve light diffusion, transparency, and visual appeal, ideal for decorative panels and display applications.

• Flexible order quantities

From small prototype runs to large-scale commercial production, sheets can be tailored to meet volume and budget needs.

________________________________________________________________________________

Frequently Asked Questions

Q1: What is GPPS and how does it differ from HIPS or ABS?

A: GPPS (General Purpose Polystyrene) is a rigid, lightweight plastic with excellent optical clarity and surface finish. Compared to HIPS, it is more transparent and brittle, while ABS offers higher impact resistance and thermoformability. GPPS is ideal for light-diffusing, decorative, and visual panels.

Q2: Can GPPS sheets be thermoformed?

A: GPPS can be lightly formed or fabricated, but it is less flexible than ABS. Proper heating and controlled processing are recommended to maintain surface clarity and prevent cracking.

Q3: Are GPPS sheets suitable for outdoor applications?

A: Standard GPPS is not UV-resistant and can become brittle if exposed to sunlight for extended periods. For outdoor use, consider ASA or UV-stabilized alternatives.

Q4: What thicknesses and sizes are available?

A: GPPS sheets can be produced in various thicknesses and custom sheet sizes to meet project requirements. Contact us for special sizes or volume orders.

______________________________________________________________________________________

👉 Browse our GPPS sheet sub-categories below or contact our team for samples and customized solutions.

Professional, custom solutions

We provide high-quality, customized plastic sheets to meet industry needs, ensuring top standards. Choose us for the perfect materials for your applications.

Custom solutions

Our expert team provides guidance with various thicknesses, sizes, and colors, ensuring quality and timely delivery.

Cross-industry use

Ta Fu Chi Plastic products in furniture, automotive, bathroom, and electronics offer functionality and aesthetics.

Innovating for lead

We develop new materials, improve production, focus on custom solutions, and stay competitive.

GPPS Plastic Sheets | Durable, High-Quality Plastic Sheet Solutions for Every Application

Ta Fu Chi Plastic Co., Ltd. is a leading GPPS Plastic Sheets manufacturer in Taiwan with over 30 years of expertise in plastic extrusion. We specialize in producing high-performance materials such as acrylic sheet, matte acrylic sheet, acrylic edge banding, and pvc wood-grain sheet, all designed to meet the evolving demands of the furniture and interior design industries. By combining advanced manufacturing processes with flexible customization options, we offer solutions that are not only visually striking but also durable, cost-effective, and easy to process. Our commitment to quality and precision has made us a trusted partner for global B2B clients across kitchen, wardrobe, and bathroom furniture manufacturing.

Headquartered in Tainan, Taiwan, Ta Fu Chi Plastic serves customers worldwide with a focus on innovation, reliability, and environmental responsibility. We continually develop materials that meet both aesthetic and functional needs—offering moisture-resistant edge banding, scratch-resistant surfaces, and rich color options. Our plastic sheets are ideal alternatives to traditional materials like glass, metal, or wood, helping manufacturers achieve modern designs with improved production efficiency. With a foundation built on customer satisfaction and long-term success, we are proud to deliver plastic sheet solutions that enhance the value and performance of today’s furniture applications.