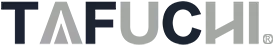

Printable HIPS Plastic Sheets – Lightweight, Durable & Easy to Fabricate Panels

Perfect for packaging, signage, and thermoformed applications.

Also known as high impact polystyrene (HIPS) sheets, Rigid Hips Plastic Sheets, and thermoformable HIPS plastic sheets.

Deliver professional-quality prints and reliable performance at a cost-effective price. Ta Fu Chi’s High Impact Polystyrene (HIPS) Sheets are lightweight, rigid, and engineered for superior printability and easy fabrication. These versatile plastic panels are ideal for indoor signage, point-of-purchase displays, product packaging, and vacuum-formed parts.

Crafted from durable HIPS material, these sheets feature a smooth matte surface optimized for screen printing, digital printing, and hot stamping. They are also easy to cut, die-cut, and thermoform, offering excellent dimensional stability and impact resistance for both visual and structural uses.

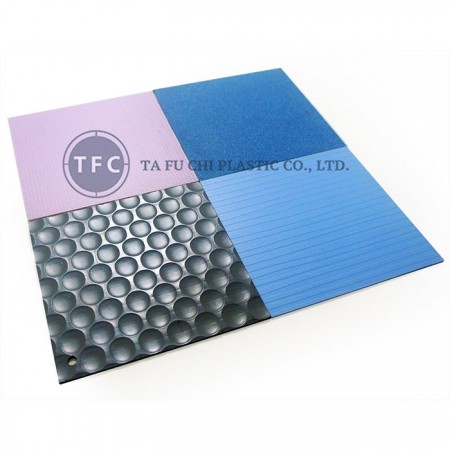

Available in a range of thicknesses, colors, and sheet sizes, our printable HIPS plastic panels can be tailored to meet the needs of OEMs, designers, and manufacturers. Whether you're creating eye-catching displays or functional packaging components, Ta Fu Chi’s HIPS sheets offer a dependable, recyclable, and efficient solution.

Frequently Asked Questions

-

Q1: Can HIPS sheets be printed, coated, or painted? How well does the surface accept ink or adhesives?

A1: Yes. HIPS sheets can be printed, coated, or painted using standard inks, UV inks, or solvent-based paints. The surface accepts adhesives well, but for optimal bonding or coating, it is recommended to clean and slightly roughen the surface. Specialized primers can further improve adhesion and durability of coatings. -

Q2: What is the difference between HIPS and GPPS?

A2: HIPS is a modified polystyrene with added impact resistance, making it tougher and less likely to crack. It is slightly flexible, suitable for thermoforming, packaging, and protective panels. GPPS is the standard polystyrene: rigid, brittle, and highly transparent. It is ideal for clear packaging, display covers, and food containers, but has lower impact strength and is prone to cracking under stress.

Applications

• Retail displays & signage for POP displays, indoor signs, nameplates, and shelf dividers.

• Consumer packaging for blister packaging, clamshell trays, and food-safe packaging (upon request).

• Thermoformed parts for lightweight formed enclosures, inserts, and custom trays.

• Industrial templates & covers for use in workshops and light equipment housing.

• Food containers & tableware for safe use in food containers and disposable tableware.

Features

- Excellent Printability – Ideal for screen and digital printing with strong color adhesion.

- High Impact Resistance – Stronger than standard polystyrene; resists cracks and dents.

- Easy to Cut & Form – Suitable for die-cutting, vacuum forming, CNC routing, and scoring.

- Customizable Colors & Sizes – Available in standard white, black, and custom color options.

- Good Dimensional Stability – Maintains shape and integrity during fabrication or thermoforming.

- Cost-Effective & Recyclable – Economical alternative to acrylic or PVC, with environmental benefits.

Specification

| Thickness | Length | Width | Color | Specification |

|---|---|---|---|---|

| 0.25mm ~ 7mm | 600mm | 600mm | White | Corona Treatment UV Resistant Forming Grade Print Grade |

| 1000mm | 1250mm | Black | ||

| 1500mm | 1830mm | Custom Size | ||

| Custom Size |

APPLICATION

- The beverage cup uses HIPS board, which is beautiful and environmentally friendly.

- Playing card can be made by polystyrene sheets.

- Cutlery trays

- seed trays

- The shell of household appliances uses HIPS to reduce production cost and gradually replace the shell formed by ABS board.

- The food lunch box uses HIPS, which is environmentally friendly and heat-resistant, and convenient to use.

- Related Products

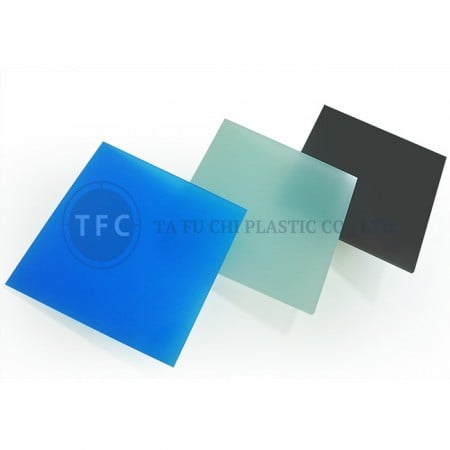

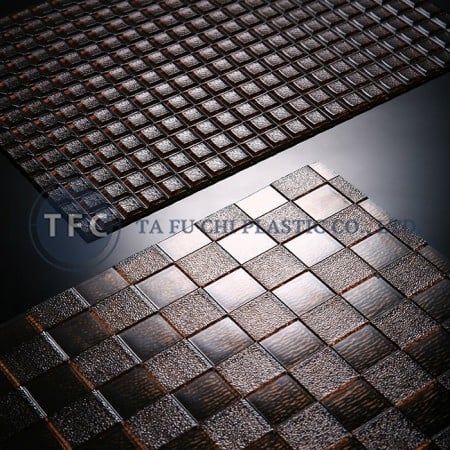

GPPS Embossed Sheets – Lightweight, Rigid Plastic Panels for Partitions & Displays

Perfect for display panels, privacy partitions,and signage.

Achieve soft lighting effects and modern aesthetics with Ta Fu Chi’s Embossed GPPS Sheets. Crafted from high-quality General Purpose Polystyrene (GPPS), these plastic panels feature a textured embossed...

Details

Professional, custom solutions

We provide high-quality, customized plastic sheets to meet industry needs, ensuring top standards. Choose us for the perfect materials for your applications.

Custom solutions

Our expert team provides guidance with various thicknesses, sizes, and colors, ensuring quality and timely delivery.

Cross-industry use

Ta Fu Chi Plastic products in furniture, automotive, bathroom, and electronics offer functionality and aesthetics.

Innovating for lead

We develop new materials, improve production, focus on custom solutions, and stay competitive.

Printable HIPS Plastic Sheets – Lightweight, Durable & Easy to Fabricate Panels | Taiwan-Based Plastic Sheet Supplier for Global Markets

Ta Fu Chi Plastic Co., Ltd. is a leading Printable HIPS Plastic Sheets – Lightweight, Durable & Easy to Fabricate Panels manufacturer in Taiwan, specializing in the production of high-quality acrylic sheet, abs sheet, hips sheet, pmma sheet, and pvc wood-grain sheet. With over 30 years of experience in the plastic extrusion industry, we are committed to providing consistent quality, customizable specifications, and advanced sheet solutions for a wide range of industrial, commercial, and furniture applications. Our in-house extrusion technology and production control enable us to deliver plastic sheets in various finishes, colors, and thicknesses that meet international standards.

As a trusted plastic extruder and OEM supplier, Ta Fu Chi Plastic has successfully manufactured and exported over 100,000 metric tons of plastic sheets worldwide. Our diverse product range includes ps embossed sheet, acrylic capped abs sheet, and other specialty sheets designed for durability, impact resistance, and aesthetic appeal. Whether used in kitchen cabinets, bathroom fixtures, automotive interiors, or signage, our products combine function and form to meet the needs of global buyers. We continue to grow as a reliable partner in delivering tailored plastic sheet solutions that enhance manufacturing efficiency and end-user satisfaction.