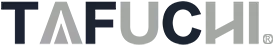

Textured ABS Panels – Thermoformable & Impact-Resistant for Industrial & Automotive Use

Lightweight Panels Ideal for Equipment Housings, Machine Covers, and Automotive Interiors

Ta Fu Chi’s textured ABS sheets, also known as embossed ABS panels or haircell ABS sheets, deliver a rugged surface texture, high impact resistance, and excellent formability. Lightweight and thermoformable, they are ideal for equipment housings, machine covers, tool boxes, and automotive interiors.Available in multiple textures, thicknesses, and custom sizes, these sheets are easy to fabricate, vacuum form, CNC machine, bond, or laminate.

ABS-based composite options include:

•ABS/ASA Sheets – enhanced UV and outdoor durability

•ASA Sheets – high weather resistance

•ABS/PMMA Sheets – high-gloss and improved weatherability

Frequently Asked Questions

-

Q1: Can textured ABS sheets be thermoformed or CNC machined?

A1: Yes. Textured ABS sheets are highly formable and machinable. They can be vacuum-formed, CNC-routed, die-cut, drilled, and bonded without damaging the textured surface when proper tooling is used. -

Q2: Are textured ABS sheets suitable for outdoor use?

A2: Standard ABS is not UV-resistant. For outdoor environments, we offer ABS/ASA co-extruded sheets or UV-stabilized ABS materials that resist yellowing, fading, and weathering. -

Q3: How durable are textured ABS sheets in daily use?

A3: Textured ABS offers excellent impact strength, moisture resistance, and surface durability. It withstands frequent handling and is suitable for indoor panels, equipment housings, and protective covers.

Applications

• Industrial Equipment Covers for durable housings and protective enclosures with high surface resistance.

• Instrument Panels & Control Boards for CNC dashboards and faceplates with anti-scratch, low-glare surfaces.

• Luggage and Case Linings for lightweight, impact-resistant interiors with decorative textures.

• Vehicle Interior Panels for RVs, utility vehicles, and specialty transports, offering durability and clean finishes.

• Commercial Interiors for wall cladding, partition panels, and architectural components that are easy to maintain.

• Display Fixtures & Retail Kiosks for professional displays and high-traffic environments, maintaining an attractive and durable appearance.

Features

- Durable Textured Surface – The embossed finish provides enhanced scratch resistance, making it ideal for high-touch applications such as machine housings and protective panels.

- Excellent Impact Resistance – ABS material is known for its toughness, helping prevent dents, cracks, or deformation under daily use.

- Consistent Appearance – Textured surface helps hide fingerprints, scuffs, and imperfections, maintaining a clean, professional look over time.

- Easy to Machine & Fabricate – Suitable for CNC machining, drilling, thermoforming, or bonding without cracking or chipping.

- Low Maintenance – Easy to clean surface requires minimal upkeep, ideal for industrial or commercial environments.

- Lightweight but Rigid – Offers the structural integrity needed for covers and panels without adding unnecessary weight.

Specification

| Thickness | Length | Width | Color | Specification |

|---|---|---|---|---|

| 0.25mm ~ 7.0mm | 1000mm | 500mm | White | Transparency ABS UV Resistant Various patterns |

| 2000mm | 1830mm | Black | ||

| 2800mm | Custom Size | Custom Color |

APPLICATION

- ABS textured plastic sheet is suitable for molding in automobile or mechanical shell which is high impact resistance.

- The cold-resistant ABS textured plastic sheet can withstand the cold weather at -20 degrees Celsius, and is often used in the refrigerated layered board and sled.

- ABS textured plastic sheet which is added UV agent is suitable for outdoor use.

- Related Products

Flat ABS Sheets – Durable, Printable & Thermoformable for Industrial & Automotive Use

Lightweight, Machinable Panels Ideal for Interior Design, Equipment Housings, and Custom Enclosures

Our ABS flat sheets are available in a wide range of thicknesses, from thin, flexible sheets for lightweight covers and displays to thick, rigid panels for CNC machining, structural use, and custom enclosures.Made...

DetailsWood Grain Plastic Sheets for Furniture & Decorative Panels – Thermoformable ABS Sheets

Designed for Stable Forming, Moisture Resistance, and Long-Term Visual Consistency in Interior Furniture Applications

ABS Wood Grain Sheets provide the natural look and texture of real wood—without the cost, weight, or maintenance. Ta Fu Chi’s wood grain ABS panels, also known as PVC-laminated ABS sheets or faux wood...

Details

Professional, custom solutions

We provide high-quality, customized plastic sheets to meet industry needs, ensuring top standards. Choose us for the perfect materials for your applications.

Custom solutions

Our expert team provides guidance with various thicknesses, sizes, and colors, ensuring quality and timely delivery.

Cross-industry use

Ta Fu Chi Plastic products in furniture, automotive, bathroom, and electronics offer functionality and aesthetics.

Innovating for lead

We develop new materials, improve production, focus on custom solutions, and stay competitive.

Textured ABS Panels – Thermoformable & Impact-Resistant for Industrial & Automotive Use | Taiwan-Based Plastic Sheet Supplier for Global Markets

Ta Fu Chi Plastic Co., Ltd. is a leading Textured ABS Panels – Thermoformable & Impact-Resistant for Industrial & Automotive Use manufacturer in Taiwan, specializing in the production of high-quality acrylic sheet, abs sheet, hips sheet, pmma sheet, and pvc wood-grain sheet. With over 30 years of experience in the plastic extrusion industry, we are committed to providing consistent quality, customizable specifications, and advanced sheet solutions for a wide range of industrial, commercial, and furniture applications. Our in-house extrusion technology and production control enable us to deliver plastic sheets in various finishes, colors, and thicknesses that meet international standards.

As a trusted plastic extruder and OEM supplier, Ta Fu Chi Plastic has successfully manufactured and exported over 100,000 metric tons of plastic sheets worldwide. Our diverse product range includes ps embossed sheet, acrylic capped abs sheet, and other specialty sheets designed for durability, impact resistance, and aesthetic appeal. Whether used in kitchen cabinets, bathroom fixtures, automotive interiors, or signage, our products combine function and form to meet the needs of global buyers. We continue to grow as a reliable partner in delivering tailored plastic sheet solutions that enhance manufacturing efficiency and end-user satisfaction.